Watertight Door

|

| watertight door |

Watertight doors are doors which

are designed to keep water out. These doors are design to

maintain the ships stability should it be involved in a

unfortunate

accident. Certain rules and regulations

adopted by the IMO require ships to be able to survive

such a tragic event. For example a ferry carrying

passengers needs to be able to withstand a flooding of

two of it's compartments.

In order to make sure these rules

are followed and still remain practical, ships make use

of watertight doors below the waterline. These doors are

usually constructed by a specialize enclosure maker, then

fitted into the ship. These doors "break" the

continuity of a structural bulkhead therefore they reduce

the strength of that bulkhead. Because of that, they must

be engineered to match the bulkhead's strength and

therefore watertight doors can look quite bulky and

menacing.

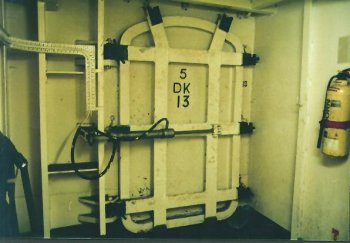

There are numerous types of doors: on deck,

some appear to be a heavy safe like doors with numerous

latching dogs around it’s perimeter. Pictured left

and below are some good examples.

There are numerous types of doors: on deck,

some appear to be a heavy safe like doors with numerous

latching dogs around it’s perimeter. Pictured left

and below are some good examples.

Below the waterline, the door are

generally of the sliding type; horizontal or vertical.

Maintenance of the doors should

consist of testing it’s full operation, and visual

check of operating mechanisms. Hoses and connections

checked for chaffing and tightness. Guides should be

clear of obstructions and greased. Wear surfaces should

be checked to to make sure they are secured and not worn

beyond tolerances. The hydraulic ram should be checked

for leaks, these can be caused by a damaged cylinder ram.

Manual pumps for the door should get a good "once

over" checking the fluid level, lever and it's

eccentrics for looseness. Check for leaks at the piping

joints.

The hydraulic power pack: Checks

include things such as hoses, fluid levels, loose wiring.

Check piping for leaks. Some

power packs have pressure reservoirs so that

doors can be actuated with a power failure. These

reservoirs store hydraulic energy by compressing nitrogen

at high pressure, these can be particularly prone to

leakage.

power packs have pressure reservoirs so that

doors can be actuated with a power failure. These

reservoirs store hydraulic energy by compressing nitrogen

at high pressure, these can be particularly prone to

leakage.

Additionally the controls for the

powerpack should be checked. Start and stop buttons,

remotes start and stop buttons should be checked for

operation with no binding. Horns are annoying and can

sometimes be found to be "un-operational".

Warning lights, if equipped, should be working. Contact

switches should be checked for operation and proper

setting.

The above,

are pictures of a vertical sliding watertight

door. It is to access the shaft tunnel. Below are

pictures of a horizontal sliding type.

The above,

are pictures of a vertical sliding watertight

door. It is to access the shaft tunnel. Below are

pictures of a horizontal sliding type.

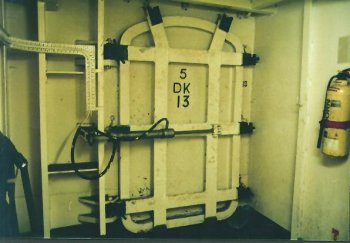

The pictures above and to the right are of

a sliding type door. By clicking on the picture to the

right you can clearly see the various points discussed

above. The manual operation crank in the foreground and

the control buttons, the grey box above the hand crank,

are clearly visible. The micro switch is at the top

corner of the door's frame. The yellow rotating light can

be seen in the upper right of the picture. Incidentally,

this picture serves to illustrate the fire pull

station as well as the fire extinguisher conveniently

located.

The pictures above and to the right are of

a sliding type door. By clicking on the picture to the

right you can clearly see the various points discussed

above. The manual operation crank in the foreground and

the control buttons, the grey box above the hand crank,

are clearly visible. The micro switch is at the top

corner of the door's frame. The yellow rotating light can

be seen in the upper right of the picture. Incidentally,

this picture serves to illustrate the fire pull

station as well as the fire extinguisher conveniently

located.

Manually operated door: Manually

actuated doors will generally have gears and long shafts

and chain drives. This is to allow operation from deck

level. If these are neglected, they could quickly lead to

some difficulties operating the door. Extra care should

be taken to maintain these components by cleaning,

greasing, and operating them.

There are numerous types of doors: on deck, some appear to be a heavy safe like doors with numerous latching dogs around it’s perimeter. Pictured left and below are some good examples.

power packs have pressure reservoirs so that doors can be actuated with a power failure. These reservoirs store hydraulic energy by compressing nitrogen at high pressure, these can be particularly prone to leakage.

The pictures above and to the right are of a sliding type door. By clicking on the picture to the right you can clearly see the various points discussed above. The manual operation crank in the foreground and the control buttons, the grey box above the hand crank, are clearly visible. The micro switch is at the top corner of the door's frame. The yellow rotating light can be seen in the upper right of the picture. Incidentally, this picture serves to illustrate the fire pull station as well as the fire extinguisher conveniently located.

Stainless steel cleaning services

ReplyDeletePickling and Passivation

Acid Pickling Passivation

Looking for Passivation services and Steel cleaning services and Pickling and Passivation wants proper services then we are here to help you right away and provides best services.