Below are

a description of the most accepted variations of the basic

principles ( above left ).

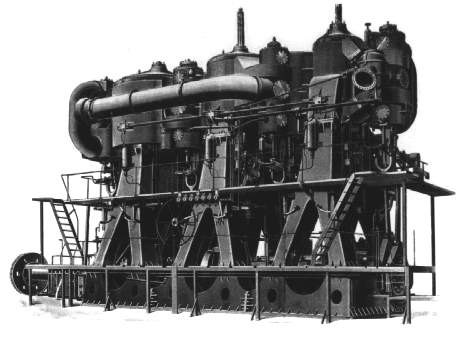

The water tube boiler

As you

can see, the Babcock Marine Water Tube Boiler (below) looks

very complicated. Thousands of tubes are placed in strategic

location to optimize the exchange of energy from the heat to

the water in the tubes. These types of boilers are most

common because of their ability to deliver large quantities

of steam.

The

large tube like structure at the top of the boiler is called

the steam drum. You could call it the heart of the boiler.

That's where the steam collects before being discharged from

the boiler. The hundreds of tube start and eventually end up

at the steam drum.

Water

enters the boiler, preheated, at the top. The hot water

naturally circulates through the tubes down to the lower area

where it is hot. The water heats up and flows back to the

steam drum where the steam collects. Not all the water gets

turn to steam, so the process starts again. Water keeps on

circulating until it becomes steam.

Meanwhile,

the control system is taking the temperature of the steam

drum, along with numerous other readings, to determine if it

should keep the burner burning, or shut it down.

As well,

sensors control the amount of water entering the boiler, this

water is know as feed water. Feed water is not your regular

drinking water. It is treated with chemicals to neutralize

various minerals in the water, which untreated, would cling

to the tubes clogging or worst, rusting them. This would make

the boiler expensive to operate because it would not be very

efficient.

On the

fire side of the boiler, carbon deposit resulting from

improper combustion or impurities in the fuel can accumulate

on the outer surface of the water tube. This creates an

insulation which quickly decrease the energy transfer from

the heat to the water. To remedy this problem the engineer

will carry out soot blowing. At a specified time the engineer

uses a long tool and insert it into the fire side of the

boiler. This device, which looks like a lance, has a tip at

the end which "blows" steam. This blowing action of

the steam "scrubs" the outside of the water tubes,

cleaning the carbon build up.

Water

tube boilers can have pressures from 7 bar

(one bar = ~15 psi) to as high as 250 bar.

The steam temperature's can vary between saturated steam, 100

degrees Celsius steam with particle of water, or be as high

as 600 - 650 degrees Celsius, know as

superheated steam or dry steam (all water particle have been

turn to a gaseous state).

The

performance of boiler is generally referred to as tons of

steam produced in one hour. In water tube boilers that could

be as low as 1.5 t/hr to as high as 2500

t/hr. The larger boilers would be land based, your local

power company would mo

st likely operate one. In

British Columbia, large boilers are most common at Pulp and

Paper plants.

Foster Wheeler (USA/UK),

Babcock (USA/UK/Ger), Combustion

Engineering (USA), and Kawasaki Heavy Industries (Japan) are some of the more

prominent manufacturer of boilers. Click on the picture to

the right to view a full size diagram of a Foster Wheeler ESD

III water tube boiler.

The fire tube boiler

This type of boilers started it all.

This is the original design of boiler which brought the tide

of power to the marine world. If you are ever in

Vancouver, BC, the

SS

Master, a turn of the century tugboat, is open for

the public to view at the Vancouver Maritime Museum. It is

operational, and a fine example of ship using a fire tube

boiler.

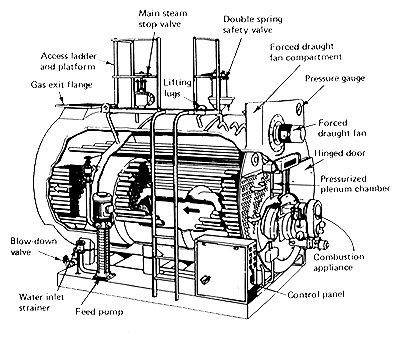

On a modern ship, the fire tube boiler

meet the ship's heating needs and is generally not used for deck

machinery. The steam produced will circulate through coils in

the cargo tanks, fuel tanks, and accommodation heating

system. They are generally supplied as a complete package,

such as the one pictured above.

This is a single furnace, three pass

type fire tube boiler. Heat - flue gases - travels through

three different sets of tubes. All the tubes are surrounded

by water which absorbs the heat. As the water turns to steam,

pressure builds up within the boiler, once enough pressure

has built up the engineer will open main steam outlet valve

slowly, supplying steam for service. Fire tube boilers are also known as "smoke

tube" and "donkey boiler".

. . . and the Auxiliary boiler

On smaller ships the auxiliary boiler

can be a stand alone unit and would most likely be of the

fire tube boiler arrangement as described above. But on a

larger vessel it is more efficient for the auxiliary boiler

to take advantage of the main engine's flue gases to heat the

water. Basically this means that the hot gases from the main

engine must pass through a heat exchanger (the auxiliary fire

tube boiler) before exiting to the atmosphere

On this diagram, look for it above, and

just aft of the main engine, near the exhaust stake of the

ship. It is called the "cargo heating boiler".

As you can imagine if the ship's main

engine was not running, there would be no hot flue gases to

make steam. The auxiliary boiler also has a burner assembly

which can be operated while the ship is in port or when the

flue gases

are not hot

enough to provide the necessary steam.

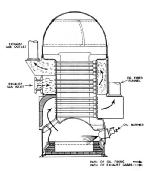

With this Cochran type boiler, the flow

of flue gases from the engine are controlled by a damper.

Should the damper not allow engine flue gases through, the

burner would automatically come on and provide heat for the

water to absorb. It would do so until the controls of the

damper allowed the flue gases to flow through the boiler

providing the necessary heat for the water, the burner would

then shut down.

Using the steam to make the ship go !

Rotating the propeller is the ultimate

goal of any power plant. As you have probably noticed, from

the text and pictures above, there is no shaft. Which leads

to the question:

"now that you have all this super

energized steam, how do you get work from it ? "

A boilers is only one part of a larger

operation, granted, it's a large part but most important part

of the operation is it's ability to apply all this steam

power.

The reciprocating steam engine.

Theory

Although the model rotates a little

fast, it clearly illustrates the action of the steam. The

superheated steam (steam @ 101+degrees Celsius) will be used

to "push" up or "down" three times in

this engine.

The first time, where the steam has the

most energy, the valve allows it to enter the small cylinder,

on the topside of the piston. The expansion (pressure) of the

steam pushes down on the area of the piston, rotating the

crankshaft. The steam is then release by ports, near the end

of it's stroke. The steam is then directed to the following

cylinder. Here for a second time, by way of a valve, the

steam enters the medium size cylinder and exert it's pressure

on the area of the piston forcing it down. Finally, with most

of the energy already spent, the steam enters the third and

final stage of the engine as it did in the two previous

stages. The steam enters the large diameter cylinder, pushes

down the piston and exits the engine. The steam is then

collected in a vacuum environment called a

condenser, where the

remaining heat in the steam is dispelled and changes state,

back to being water. The water is then fed, or should I say

recycled, as feedwater for the boiler.

The pistons of this engine are called

double acting, which means that, not only does the piston get

"pushed down" but it also gets "pushed

up". The three stages describe above are also,

simultaneously, happening to the underside of the piston. So

steam enters the top of the piston, pushes it down, then the

valve allows steam to enter the bottom of the piston, pushing

it up.

The Steam Turbine

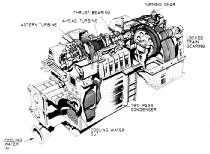

The more modern method of extracting

mechanical energy from heat energy is the steam turbine.

Steam turbine have been the norm in various land based power

plants for many years. BC Hydro's

Burrard Thermal Plant just outside Vancouver is very similar to many power

plants in most countries, and a good

example of a steam power plant. The Burrard Generating Station is a

950 MW conventional natural gas-fired generating station.

It's large boilers create large amounts of steam which is then fed to steam

turbines. The turbines rotate large alternators, which produce electrical

energy. On a ship, the operation is generally smaller, even on very large

super tankers. On a ship, the turbine is connected to a reduction gear,

which drives a propeller, producing motion instead of electrical energy.

If you can imagine a pinwheel, held

solidly near your mouth, then blowing, at the right angle,

air unto each "blade" of the pinwheel. You see the

whole pinwheel turn. The principle of the impulse turbine is

much the same.

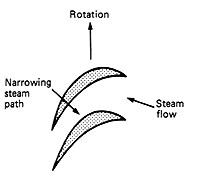

The impulse turbine contains several

"pinwheels" which are actually called turbine

rotors, pictured to the right. The rotors can rotate on a

shaft, but cannot slide for and aft. "In front" of

these rotors are nozzles, drilled into the stationary part of

the turbine. Because steam does not like to be confined, each

nozzle ejects steam onto one blade of the rotor, much like we

imagined with the "pinwheel". Because the shape of

the blades is at an angle, the jet of steam must change

direction. This change in direction results in a force,

rotating the rotor which rotates the shaft.

One set of turbine rotor and stationary

nozzles is called a stage. Much like the triple expansion

piston type engine, mentioned above, the steam travels

through many stages. In the case of steam turbines, the steam

proceeds through one stage, then collects and proceeds to the

second stage and so on. Each time, the steam proceeds to a

larger diameter rotor turbine, until the most of it's energy

has been exerted on the rotors of the turbine. The energy

depleted steam is drawn, by vacuum, to the

condenser where it is

cooled to form feed water, ready to feed the boiler once

again.

As with any

machine, improvements and specific designs have evolved to improve the

overall efficiency of the machine. One turbine design is the impulse

design as describe above. Another is the reaction type

turbine, both types are illustrated below. A third is more of

a hybrid design, combining, actually compounding, features

from the impulse and reaction type steam turbines.

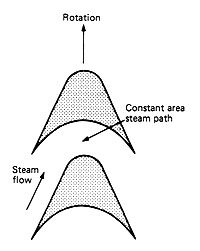

The impulse design

(above left) relies on stationary

ring of steam nozzles to direct flow onto the blades of

a rotor. In the reaction type (above right), the flow of steam must pass through the rotor.

The rotor is made up of blades, just like the impulse type,

but in this case the blades

are curved to

provide a slight nozzle shape.

The blades on the impulse type change

the direction of the steam, whilst in the reaction, the

blades become the nozzles. The illustration above show the

differences between the two types. The images to the right, courtesy of Rick

Boggs' Merchant Marine and

Maritime Pages,

illustrates a reaction type steam turbine.

Steam turbines rotate at very high

speeds but in order to get the most efficiency from the

propeller, the propeller must turn slow. Therefore a marine

gear must be used. Marine gears are very common place, they are

used to transform power from an engine to the actual machine

doing the work, in this case the propeller.

st likely operate one. In British Columbia, large boilers are most common at Pulp and Paper plants.

Foster Wheeler (USA/UK), Babcock (USA/UK/Ger), Combustion Engineering (USA), and Kawasaki Heavy Industries (Japan) are some of the more prominent manufacturer of boilers. Click on the picture to the right to view a full size diagram of a Foster Wheeler ESD III water tube boiler.Vancouver, BC, the SS Master, a turn of the century tugboat, is open for the public to view at the Vancouver Maritime Museum. It is operational, and a fine example of ship using a fire tube boiler.

On a modern ship, the fire tube boiler meet the ship's heating needs and is generally not used for deck machinery. The steam produced will circulate through coils in the cargo tanks, fuel tanks, and accommodation heating system. They are generally supplied as a complete package, such as the one pictured above.This is a single furnace, three pass type fire tube boiler. Heat - flue gases - travels through three different sets of tubes. All the tubes are surrounded by water which absorbs the heat. As the water turns to steam, pressure builds up within the boiler, once enough pressure has built up the engineer will open main steam outlet valve slowly, supplying steam for service. Fire tube boilers are also known as "smoke tube" and "donkey boiler".are not hot enough to provide the necessary steam.

With this Cochran type boiler, the flow of flue gases from the engine are controlled by a damper. Should the damper not allow engine flue gases through, the burner would automatically come on and provide heat for the water to absorb. It would do so until the controls of the damper allowed the flue gases to flow through the boiler providing the necessary heat for the water, the burner would then shut down.triple expansion steam engine. The Famous RMS Titanic had two similar engines, except the Titanic's had an additional stage. They were known as quadruple expansion engine and operated on the same principle.

Although the model rotates a little fast, it clearly illustrates the action of the steam. The superheated steam (steam @ 101+degrees Celsius) will be used to "push" up or "down" three times in this engine.The first time, where the steam has the most energy, the valve allows it to enter the small cylinder, on the topside of the piston. The expansion (pressure) of the steam pushes down on the area of the piston, rotating the crankshaft. The steam is then release by ports, near the end of it's stroke. The steam is then directed to the following cylinder. Here for a second time, by way of a valve, the steam enters the medium size cylinder and exert it's pressure on the area of the piston forcing it down. Finally, with most of the energy already spent, the steam enters the third and final stage of the engine as it did in the two previous stages. The steam enters the large diameter cylinder, pushes down the piston and exits the engine. The steam is then collected in a vacuum environment called a condenser, where the remaining heat in the steam is dispelled and changes state, back to being water. The water is then fed, or should I say recycled, as feedwater for the boiler.The pistons of this engine are called double acting, which means that, not only does the piston get "pushed down" but it also gets "pushed up". The three stages describe above are also, simultaneously, happening to the underside of the piston. So steam enters the top of the piston, pushes it down, then the valve allows steam to enter the bottom of the piston, pushing it up. The impulse design (above left) relies on stationary ring of steam nozzles to direct flow onto the blades of a rotor. In the reaction type (above right), the flow of steam must pass through the rotor. The rotor is made up of blades, just like the impulse type, but in this case the blades

The impulse design (above left) relies on stationary ring of steam nozzles to direct flow onto the blades of a rotor. In the reaction type (above right), the flow of steam must pass through the rotor. The rotor is made up of blades, just like the impulse type, but in this case the bladesare curved to provide a slight nozzle shape.

The blades on the impulse type change the direction of the steam, whilst in the reaction, the blades become the nozzles. The illustration above show the differences between the two types. The images to the right, courtesy of Rick Boggs' Merchant Marine and Maritime Pages, illustrates a reaction type steam turbine.Steam turbines rotate at very high speeds but in order to get the most efficiency from the propeller, the propeller must turn slow. Therefore a marine gear must be used. Marine gears are very common place, they are used to transform power from an engine to the actual machine doing the work, in this case the propeller.

Been looking for such an amazing web journal like this for quite a while.

ReplyDeleteJohnson outboard lower unit tools