|

| Add caption |

Theoretical suction volume Vs

For greater efficiency air compression should be isothermal as this requires the minimum work input. In practice Isothermal compression is not possible, an ideal Isothermal cycle requires sufficient time to allow all the required heat to be transferred out of the cylinder, practicality dictates that the piston must have a relatively high speed to give a reasonable output,

Cylinder cooling on a single stage compressor gives better efficiency but there is a limitation in the surface area to cylinder volume that can be used for cooling effect, but multistage compressors with an efficient extended surface interstage cooler gives cycle improved compression efficiency better approaching that of the isothermal. In theory the greater the number of stages the closer the curve will approach the ideal isothermal compression curve, however there is an increase in cost, complexity, and the law of diminishing returns limit the number.

Compression in stages has the following advantages;

The compression ratio at each stage is lower and so the final temperature is lower. This reduces problems with lubrication

. The machine is smaller and better balanced

water can be drained off at each stage

Compression better approaches the ideal isothermal

It is important that the compressor clearance volume is kept small as possible in order to improve overall volumetric efficiency as the air trapped in this space must expand to below suction pressure before new air can enter, this is an effective loss of stroke.

A clearance is required in order to prevent the piston striking the cylinder cover when starting or stopping off load. The clearance volume is sometimes referred to as the 'Bump Clearance'.

Crankcase lubrication

Lubrication of the crankcase in a compressor does not pose any specific problems and normally consist of splash lubrication with pressurised oil being fed to shell bearings. Where drip cylinder lubrication is used, this should be kept to a minimum conducive with liner wear. A standard mineral oil similar to that used in the main engine may be used, although due to carbon deposits, higher quality oils are generally used with the most effective being specifically designed synthetics which have allow a considerable reduction in maintenance but are costly.

Mineral oils contain a blend of lighter elements such as paraffin's, and heavier elements such as asphaltenes. During compression the lighter elements are vaporised leaving the heavy ends, these coat the piston rings and discharge valves in combination with oxidised oil deposits. These deposits also coat passage ways and coolers resulting in higher interstage air temperatures. Deposits on discharge valves cause them to become sticky and leak resulting in hot air being drawn back into the cylinder for recompression. This increases the temperature and hence causes greater oxidation and deposits, and so the condition deteriorates with increasing rapidity.

Temperature can become very high, this may result in oily deposits at the discharge valves carbonising. Eventually this carbon could glow red and cause detonation. It is more likely, however, that oily deposits will be carried over to the air receiver and air start manifold to be ignited by blowpast at the cylinder air start valve.

Deposits at piston rings cause leakage allowing oil to enter the cylinder from the crankcase thus increasing the danger it is essential that crankcase lubrication be kept to a minimum compatible with an acceptable wear rate. Regular maintenance will minimise oily deposits build up and hence the risk of explosion

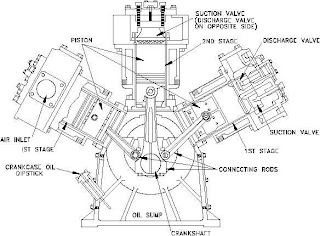

Materials and design of a reciprocating compressor

The compressor casing, cylinder covers and piston rings are generally of cast iron. Pistons may be of cast iron, steel of aluminium. Aluminium being the preferred material for use on the LP piston due to its larger diameter. Valves are usually made so that parts can be interchanged between the suction and discharge valves. Seats are of mild steel with small diameter air passages to prevent the fragments of broken valve plate from entering the cylinder. Valve plates are of vanadium steel heat treated and ground to provided the required hardness and surface finish. Springs should be arranged such that they lift and seat squarely. Uneven spring force or deposits on the seat cause valves to bend resulting in fatigue cracking.

Bursting valve arrangement

For compressors designed for starting air requirements a water jacket relief valve is fitted.

reciprocating compressor arrangement

Rotary Compressor

rotary compressor arrangement

The rotary compressor may be of the impeller type similar to that used in the turbocharger , scroll, twin rotating lobes or of the sliding vane type similar to the one shown above. In practice there would be several more vanes than shown.

Rotary compressors are capable of handling large quantities of low pressure air much more efficiently than a reciprocating compressor. In order to produce increased pressures it is possible to stage rotary compressors but leakage problems increase at higher pressures as well as stress on the vanes.

The sliding vane compressor consists of a slotted rotor with its axis offset from that of the cylindrical casing. Vanes fit in the slots and have contact with the casing

On the suction side the space contained between the casing, the rotor and an adjacent pair of vanes is gradually increasing allowing air to be drawn in.

On the compression side this same space is gradually reduced causing the pressure increase. When the leading vane uncovers the discharge port air will flow to outlet. Larger compressors of this type are water-cooled, smaller compressors tend to be air cooled.

The main problems related with sliding vane compressors concern wear at the vane tips and sealing of the ends

Rotary/reciprocating Compressor

Rotary compressors in general do not require internal lubrication but they are not suitable alone for providing air at a pressure for starting duties. They can, however, be linked to reciprocating stages to produce a hybrid compressor.

The compressor is lighter, more compact and better balanced than an equivalent all reciprocating unit. In basic terms the rotary first stage supplies air to the reciprocating second and subsequent stages. All stages being driven by the same shaft

rotary/reciprocating compressor arrangement

Safety Valve

Materials

Cast iron-Casing, Liners, Pistons( the LP piston is sometimes made from an aluminium alloy, Cylinder covers Steel- Crankshaft, Conrods, Pistons, Valve seats Vanadium Steel- Valve plates

Starting air compressor circuit

Starting and stopping sequence is adjustable, the magnetic valves are open when the compressor is stopped so any residual pressure is blown off. On starting the magnetic valve are sometimes delayed to close so as to allow the compressor motor to reach full speed before the compressor is loaded up.

The non-return valves prevent HP air leaking back from the receiver on which the filling is also of the non return type.

diagram of electrical starting arrangement

Calculation of required cylinder compression for a multistage reciprocating compressor

r = stage pressure ratio

R = compression pressure ratio

for a two stage

r = R1/2

for a three stage

r = R1/3

for example, a 3 stage compressor requiring a final pressure of 64bar would have the following interstage pressures 1st stage 1bar compressed to 4bar

2nd stage 4bar compressed to 16bar

3rd stage 16bar compressed to 64bar

It would appear that most of the work is being carried out in the final stage, this is untrue as with the increase in pressure is a complimentary reduction in volume, if the temperature conditions remain the same then work will be equally divided between the stages.

By reducing the suction pressure, the cylinder is required to do more work on the air before the discharge valve opens. This means that the air will be delivered at a higher pressure. The higher temperature can lead to problems with the cylinder lubrication as well as a drop in efficiency as well as carbonising of the oil and increased deposits on the valves and piston rings and interstage passages. In the extreme it can lead to seizure and possible diesel detonation of the oil laden air.

The reduction in pressure at the suction can be due to a partially blocked suction filter or partially choked suction valve. The lower pressure conditions in the cylinder at the start of compression can cause oil laden air to be drawn from the crankcase up the liner. This oil can lead to increased deposits in the compressor as well as further downstream in the distribution system

(P1.V1)/ T1 = (P2. V2)/T2

and

(P1/P2).(T2/T1) = (V2/V1)

P1.V1g = P2.V2g

and

P1/P2 = V2g/V1g From these we get;

T2 = T1. (P2/P1) (g -1)/g

g = 1.4

and if we take for and example

P1 = 0.4 bar

P2 = 1 bar

Pf = 5 bar

Tinitial = 300 K we end with final temperatures for the two compression's of

T1= 617 K and T2 = 475 K

from the graph it can be clearly seen that losses due to the bump clearance has increased and the period of constant pressure delivery has been reduced.

Coolers

Plain Tube-

-easy to clean

-very effective due to large surface area of large number small diameter tubes

-plugging of failed tube allos cooler to continue in service with little loss in efficiency

-must allow for thermal expansion by having one tube plate floating

'U' tube-

-suitable for higher pressures than plain tube

-self compensating for thermal expansion

-efficent due to large nomber small diameter tubes

-failed tubes may be plugged

-more expensive than plain tube and diificult to clean

Coil tube

-self compensating for expansion

-suitable for high pressures

-difficult to clean

-inefficicent due to large tube diameter

- not easy to plug

-expensive

Tube intercooler

U - Tube intercooler

Coil Intercooler

Great article about air compressors did you know affordable air compressors here in australia

ReplyDeleteThe Air Compressors can be acquired in various models from us. We provide Air Compressors at market-leading price to the buyers. For more details about air compressor price.

ReplyDeleteThis article is definitely worth saving to the favorites. I read just about everything on this subject and most of it. This material is quite a bit different in that the

ReplyDeleteinformation is up to date and written by an author that is on the cutting

edge of the subject.

Mechanical boosters

Industrial blowers

The information on this topic is really one particular of the most effective

ReplyDeletesubstance that We have actually appear throughout. I adore your publish thanks a lot.

http://tinyurl.com/omgnay9

http://tinyurl.com/op2y5mq

http://tinyurl.com/pbn2y83

http://tinyurl.com/ndqyqe2

great information

ReplyDeleteAir Dryer | Refrigerated Air Dryer | Heatless Air Dryer

yes you say correct that air compressor was very helpful for every one

DeleteOne more thing that you need to know is how big you want your compressor to be. This would depend on how many tools do you intend to use it with at a time. A rule of thumb when buying one is to get one that has a CPM that is slightly higher than the minimum requirement of the tool you intend to use it with. Small compressors are good for powering small tools that don't require that much power. But again if you intend to power heavy-duty equipment with it, get the big one instead.

ReplyDeleteAir Machines

thanks for sharing this information

ReplyDeleteair dryer | refrigerated air dryer | Heatless air dryer

As compressed air specialists, Cooper Freer provides high quality air compressor, tools and accessories in Nottingham, Derby, UK, Milton Keynes, Kettering, Coventry, and Lincoln. We completely understand the needs of our customers and provide them reliable and energy efficient equipment.

ReplyDeleteThanks for sharing the information about air compressor.

ReplyDeletecompressors in erode

Thank you for your blog. This is useful information.

ReplyDeleteAir Compressor

The post is written in very a good manner and it entails many useful information for me. I am happy to find your distinguished way of writing the post. Now you make it easy for me to understand and implement the concept.

ReplyDeleteAir Compressor

Compressors are a need for both commercial and residential buildings. This list contains names of the top suppliers that offer the most comprehensive collection of the best solutions in the market. You can rely on them to understand your varying requirements and accommodate them perfectly. You will find a wide collection of the highest quality air compressors in their collection and will be able to choose the best one for all your different needs. These providers have worked with a variety of clients in the market and are known to provide the best quality equipment that will help you integrate better air compression in your buildings and help you streamline your buildings in no time. These suppliers have years of experience in the industry and offer a wide range of high-quality air compressors to help you improve the functioning of your building. Browse the collection of the best suppliers and choose an ideal supplier for your varying needs today!

ReplyDeleteClick here to see the details -> Visit official website

This is very nice information, Thank you so much for sharing your knowledge. Screw Air Compressor

ReplyDeleteNice articles and your information valuable and good articles thank for the sharing information Industrial air receivers

ReplyDeleteNice articles and your information valuable for us.

ReplyDeleteCold Storage Equipment supplier In Delhi

Nice articles and your information valuable and good articles thank for the sharing information Air manifold system suppliers

ReplyDeleteNice explanation of Reciprocating Air Compressors. The points on pressure capability and maintenance are especially relevant. From an industry perspective, correct application and upkeep really impact long-term performance. Thanks for sharing!

ReplyDelete