|

| Add caption |

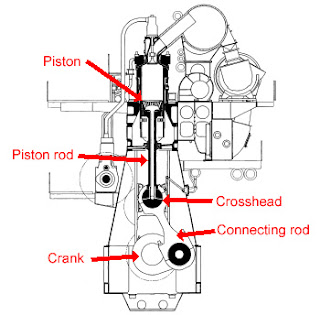

Description of the salient parts

Modern engines designed for increasing power to weight ratios are reliant on not only stronger materials but also on careful design. Each component design must not only be optimised for its own purpose, but also in some cases, to provide strength to the overall structure.

An example of this is how the bedplate and A-frame combine to create a strong rigid box able to resist the forces of combustion and maintain essential alignment for the crankshaft and over moving parts.

The entablature not only supports the cylinder liner and head it also creates areas for cooling water and scavenging air.

Fabrication techniques are extensively used simplifying castings and speeding assembly times by reducing the number of fastening.In order to obtain ideal strength transfer between components the fastenings must have intermit contact with the surfaces of the components and hence fitted bolts are used.

Cylinder blocks must be cast, due to the difficulties in casting large components generally single cylinder blocks are created joined to each other and to a common fabricated A-frame/bedplate box.

Bedplate

The bedplate acts as the main strength member, maintains correct alignment and supports the weight of the components. it must be capable of withstanding the fluctuating forces created during operation and transmit them to the ships structure.

In addition it may also collect lubricating oil.

In slow speed engine design, it consists of a deep longitudinal box section with stiffening in the form of members and webs.

Transverse members are fitted between each throw of the crankshaft. These support the main bearing saddles and Tie -rod connection. They are attached to the structure by substantial butt welds.

To reduce the engine height the sump of the bedplate may be sunken allowing it to fitted into a recess in the ships structure.

Plate and weld preparation is required with welds of the double butt type if possible. Regular internal inspection of the parts especially the transverse girder is required for fatigue cracking. Tie bolts should be checked for tighteness.

Box girders-A box girder is stronger and more rigid then I or H section girder of the same c.s.a.

From the simple beam bending equation we have;

M /I = s /y = E/R

M=Bending moment

I=2nd moment of area of the cross section

s =Stress

y=distance from the axis of bending to the outer face

E= modulus of elasticity

R-radius of curvature of the bending.

This can be arranged into

s = (M/I) . y

It can be seen that for the same bending moment on a symmetrical shape of same size, the stress is reduced on the increasing 2nd moment of area. The second moment of area increase with moving of material away from the axis of bending towards the extremes of the section.

Because of this the commonest way of construction a fabricated bedplate is by creating two box section girders and tie them using transverse girders.

Welded bedplate

The advent of the small bore slow speed has seen the use of single side bedplates. A box section is then created by using a box section crankcase structure rather than the more traditional A-frame.This has the advantages of reducing width as well as weight and increasing the amount of fabrication so reducing assembly times.

Modern welded bedplate

Due to the weight penalty, the use of cast iron is generally limited to smaller units where fabrication becomes impractical. However, cast iron has internal resilience allowing it to dampen down vibrations, this has led to its usage on some medium speed installations, especially passenger carriers, where noise and vibration suppression is important. .

The most highly loaded pat of a bedplate is the transverse girder. Classification societies require that residual stress is removed after construction.

The transverse girder acts as a simple beam with the forces of combustion acting on the piston passing down through the bearing. The forces acting on the head are passed through the Tie rods.

Forces acting on transverse girder

It can be seen that to reduce the bending moment the tie rods have to be brought closer to the crankshaft. The limit to this is the securing arrangement required for the main bearing keep. One method is to use two instead of one bolts which can be made of smaller diameter. Sulzer use an alternative and very successful method in the form of jacking bolts. These jack against the bottom of the A-frame.

Sulzer amin bearing arrangements .

Superlong stokes

The increasing stroke to bore ratio has led to several problems not least of which is cylinder lubrication, thermal gradients over stroke, starting etc. I addition there is a necessity to dampen rotational vibrations over the engine height by means of hydraulic stays attached to the ships structure. These reduce the movement of the engine without allowing excessive vibration to be transmitted to the hull.

Staying of tall engines

Camshaftless engines

The camshaftless two stroke crosshead engine has two main advantages;

Firstly it simplifies engine design in particular negating the need for chain or gear driven camshafts. This allows a net reduction in weight, simplifies engine erection and removes some physical constraints for future engine design.

Secondly, it allows for finite control of parameters such as fuel delivery volume and timing, and exhaust valve opening and closing times.

Traditionally fuel, exhaust valve opening, starting air and cylinder lube oil delivery are all controlled by camshaft lobe design. It is possible now to control these using high reliability solenoid valves. This method is used on the sulzer RT-flex engine

Fuel control

Schematic of camshaftless fuel system

Fuel is delivered to a common rail by a high efficiency fuel pump operated by a multilobe cam driven off the main engine crankshaft.

A control unit activates electric solenoid valves to deliver fuel to the appropriate cylinder injectors.

This allows control of fuel volume, fuel delivery progression ( that is the shape of fuel delivery- e.g slow than fast) and precise timing. It means that fuel ignition quality and condition at delivery can be taken into account.

Exhaust valves

Exhaust valves are operated in the normal way via hydraulic pushrods. However hydraulic oil delivery is not by individual pump but by common rail supplied by a high capacity, high pressure servo pump. The engine management control unit operates the exhaust valves by energising the appropriate solenoid valve. Other starting air valves and cylinder lube oil are all similarly controlled by the engine management control unit via solenoid valves

Modern developments

The modern trend has followed the smaler and lighter rule with an ever increaseing power to weight ratio. In addition to this simplified maintenance and production proceddures have been incorporated.

Intelligent engines without camshafts are being introduced enabling increased efficiency with reduced fuel quality. Intelligent engines also allow for increased efficiency when running at part load.

Liners

Modern requirements for the design and contruction of a cylinder liner include;

Material with sufficient hard phase and ductility

Smooth surface finish

Full honing of running surface

Bore cooling of liner and components surrounding combustion chanmber- the insertion of insulating tubes into the bore cooling holes of liners is sometimes necessary to prevent undercooling and allow a standard liner to be used with different ratings.

Critical profiling of liner wall thickness to stabilise temperatures and prevent corosion attack

Multi-level cylinder lubrication with variable speed (load dependant) pumps

Efficient water removal from scavenge air

Pistons

High topland ( the 1st piston ring is positioned will below the upper surface of the piston) with asociated reduced ring heat load has given better ring pack performance by improving working conditions for the cylinder lube oil. The disadvantage of this system is that a coke build up can occur aboth the piston which leads to 'bore polishing'. This polishing reduces the ability of the cylinder lube oil to 'key' into the liner therefore increased cylinder lube oil consumption/increased liner wear can result. To combat this piston cleaning rings are incorporated into the liner. These slightly reduce the bore removing the depoisits.

0 Cross section showing piston cleaning ring

No comments:

Post a Comment