|

| Add caption |

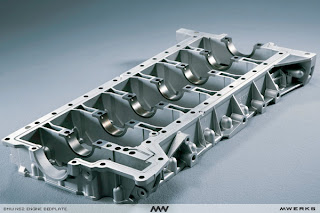

Transverse members are fitted between each throw of the crankshaft. These support the main bearing saddles and Tie -rod connection. They are attached to the structure by substantial butt welds.

To reduce the engine height the sump of the bedplate may be sunken allowing it to fitted into a recess in the ships structure.

Plate and weld preparation is required with welds of the double butt type if possible. Regular internal inspection of the parts especially the transverse girder is required for fatigue cracking. Tie bolts should be checked for tighteness.

Box girders-A box girder is stronger and more rigid then I or H section girder of the same c.s.a.

From the simple beam bending equation we have;

M /I = s /y = E/R

M=Bending moment

I=2nd moment of area of the cross section

s =Stress

y=distance from the axis of bending to the outer face

E= modulus of elasticity

R-radius of curvature of the bending.

I=2nd moment of area of the cross section

s =Stress

y=distance from the axis of bending to the outer face

E= modulus of elasticity

R-radius of curvature of the bending.

This can be arranged into

s = (M/I) . y

It can be seen that for the same bending moment on a symmetrical shape

of same size, the stress is reduced on the increasing 2nd moment of

area. The second moment of area increase with moving of material away

from the axis of bending towards the extremes of the section.Because of this the commonest way of construction a fabricated bedplate is by creating two box section girders and tie them using transverse girders.

The transverse girder acts as a simple beam with the forces of combustion acting on the piston passing down through the bearing. The forces acting on the head are passed through the Tie rods.

I am the author of marineengineering.org.uk which most of the work on your website has been copied against which you are making financial gain. If you do not gain permission or remove it I will take further action. My site is non-commercial, I note you have placed content from marinediesels.info which is a commercial site, you are in breach of his copyright and as such ne may not be as generous in allowing you time to remove his work before taking further action.

ReplyDeletebrian